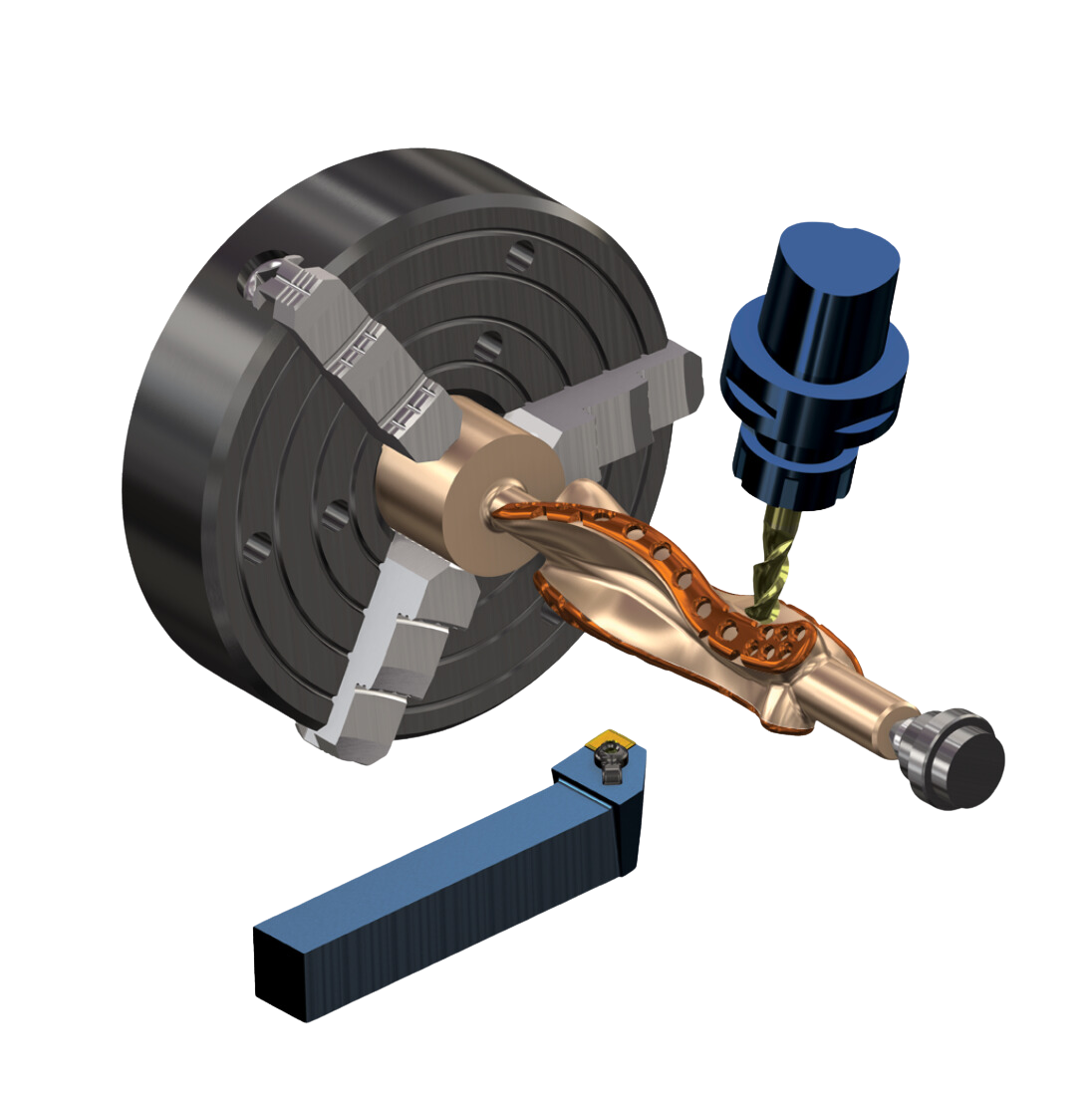

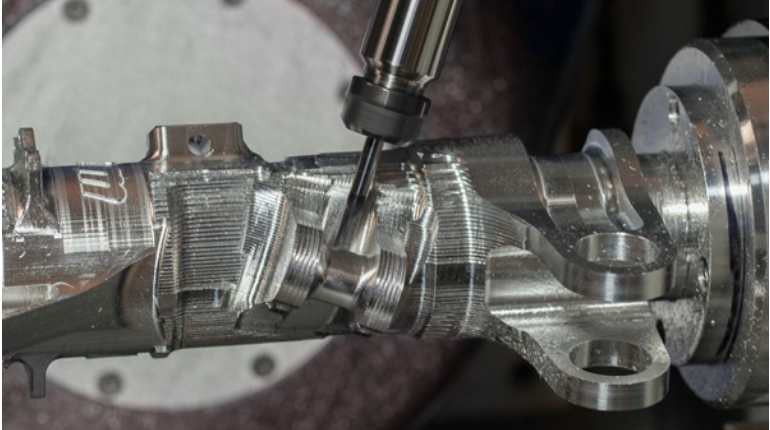

Mastercam Mill-Turn is a cutting-edge software solution that revolutionizes the way you handle CNC machining operations. Whether you’re a small machine shop or a large manufacturing facility, Mastercam Mill-Turn provides you with the tools and capabilities you need to streamline your processes, reduce cycle times, and improve overall productivity.

These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

Key Features

CAD for

CAM

A full design package based on a machinists needs including wireframe, surfaces, and solids design; open most CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Advanced

Technology

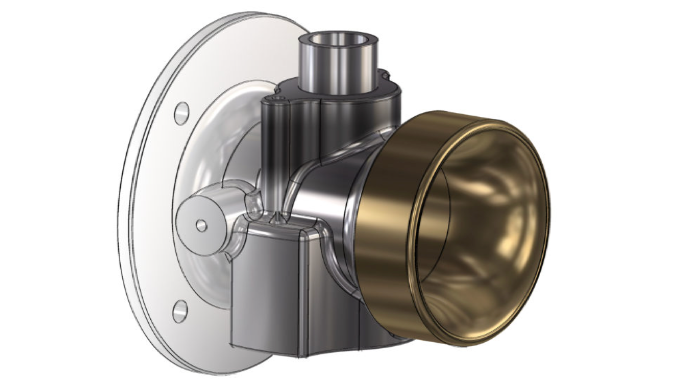

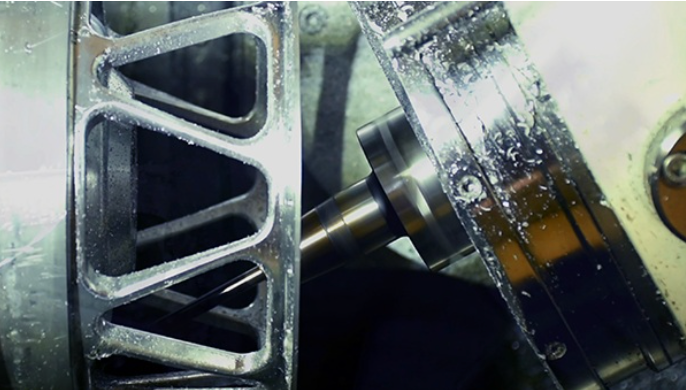

Mastercam’s proven toolpaths, intuitive part handling, automated job setup, 3D tooling support, customized milling tools optimized for mill-turn machining, deburring, support for 2- through 5-axis toolpaths, multiturret, multispindle, and more—all managed in a single machine environment.

Machine

Simulation

Detect collisions between your stock, tool, and machine components before sending code to your machine tool. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis toolpaths to make clean, efficient, and accurate programs.

This lathe mill combination programming software provides a set of routines to program complex parts and test your cutting strategies in a single environment—before your stock is on your multitasking machine. You can use Mill-Turn to machine parts without fear of costly collisions or machine damage.

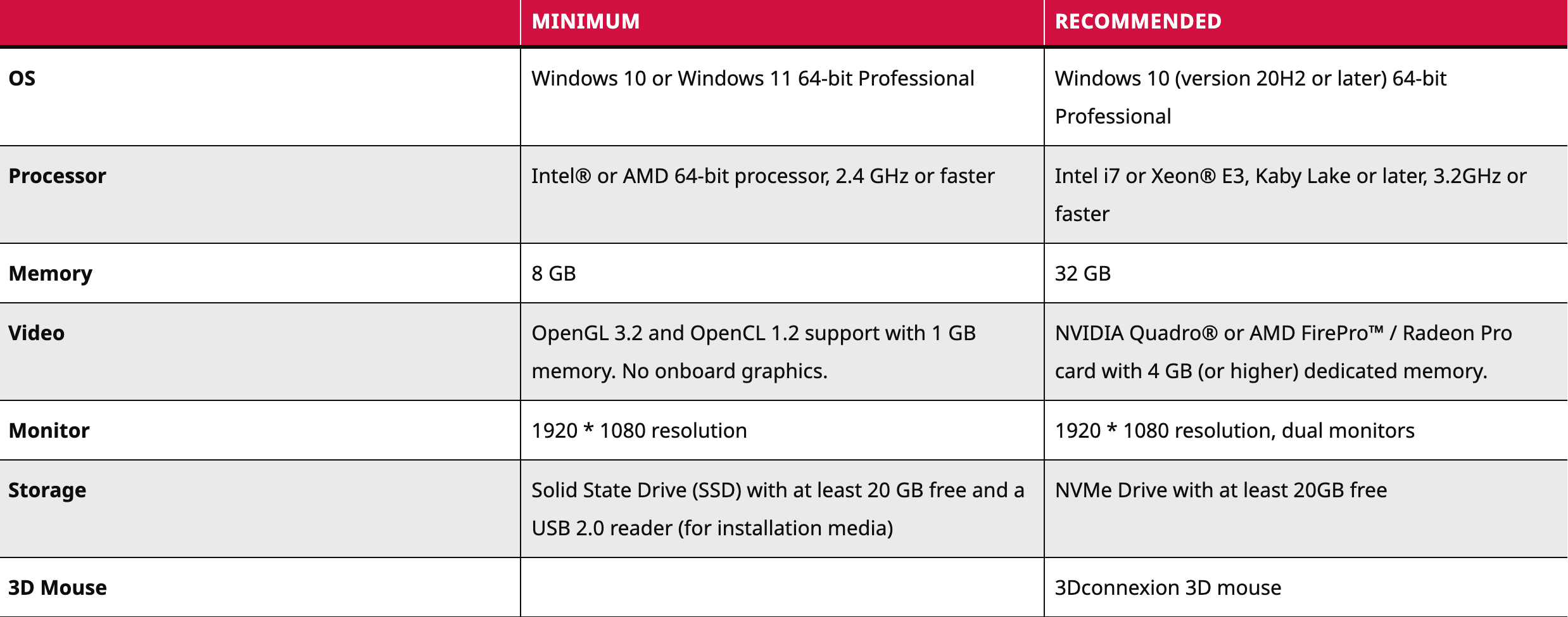

System

Requirements

See the table for minimum and recommended system configurations for Mastercam.

These recommendations are based on systems that Mastercam uses for testing and evaluation purposes. Our recommendation is to get as much power (processor, video card, and memory) for your systems as you can afford.

It All Starts With a Discussion!

Contact us today to unlock the potential of precision manufacturing with Mastercam. Your success is our mission.

Complete the form or give us a call

7885 W 48th Ave

S. Wheat Ridge, CO 80033

info@mastercamdenver.com